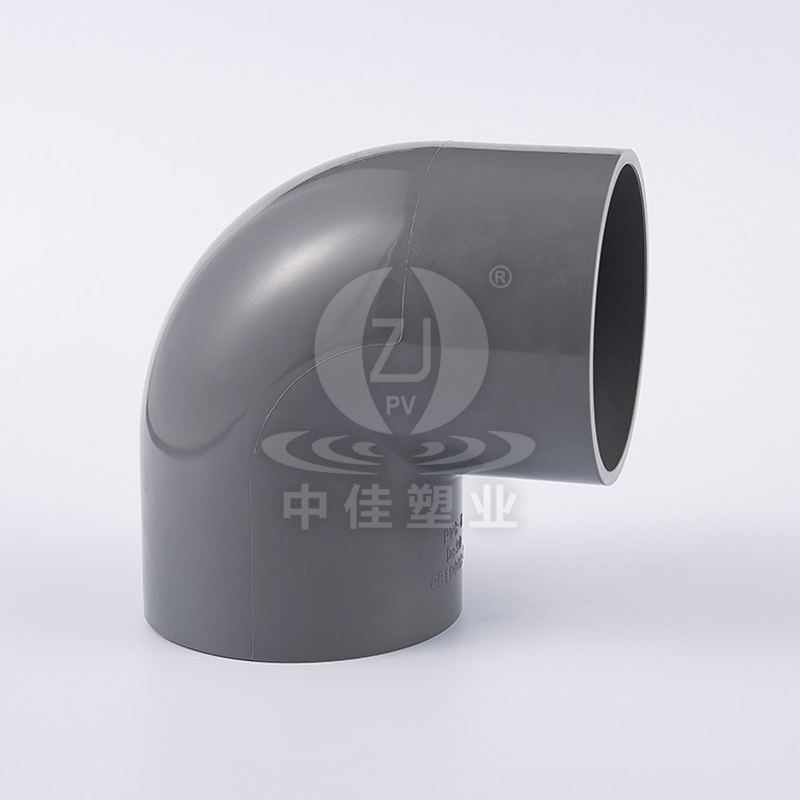

In modern buildings, water supply and drainage, ventilation and other piping systems, pipe connection and turning are crucial links. Plastic UPVC Elbow 90 Degree is a common pipe fitting widely used in various industrial and civil fields. It is mainly used to turn the pipe at a 90-degree angle to achieve the reasonable layout and space utilization of the pipe.

UPVC material is a plastic without plasticizer and high hardness. It has excellent corrosion resistance, high strength and light weight, so it is particularly suitable for various pipe connection and bending needs.

Construction characteristics of plastic UPVC 90 degree elbow

Material selection:

Plastic UPVC 90 degree elbow is made of non-plasticized polyvinyl chloride material, which does not contain harmful ingredients and has good corrosion resistance. It can withstand the erosion of a variety of chemical substances and adapt to the use requirements in various environments.

Design and structure:

The design of the 90-degree elbow is simple and practical. Its internal surface is smooth, the flow resistance of the fluid is small, and the pressure loss of the fluid can be effectively reduced. The shape of the elbow is usually a standard pipe connection size, ensuring a tight connection with other pipes and accessories.

Connection method:

Plastic UPVC 90-degree elbows are usually connected to pipes by bonding or threading. Bonding connection firmly connects the elbow to the pipe through a special adhesive, while threaded connection achieves quick installation through threads.

Application areas of plastic UPVC 90-degree elbows

Water supply and drainage system

Plastic UPVC 90-degree elbows are widely used in water supply and drainage pipe systems in buildings. It is used to connect pipes at different angles to ensure unobstructed water flow. The corrosion resistance of UPVC materials makes it an ideal choice, especially for urban water supply and drainage systems.

Chemical transportation

In the chemical industry, plastic UPVC 90-degree elbows are often used to transport various chemical liquids, acid and alkali solutions and other corrosive substances. Since UPVC materials have strong corrosion resistance to most chemicals, they can ensure the long-term and stable operation of the pipeline system.

Ventilation system

Plastic UPVC 90-degree elbows are also widely used in ventilation systems. Through the clever design of the elbow, the direction of air flow can be changed by 90 degrees, ensuring that the ventilation system can operate smoothly and achieve the expected effect.

Electrical Pipeline System

In electrical pipelines, UPVC 90-degree elbows are used for cable protection and turning. Its waterproof, insulating and corrosion-resistant properties make it widely used in electrical facilities, especially in some humid or corrosive environments, and can provide long-term stability.

Agricultural Irrigation

In agricultural irrigation systems, UPVC 90-degree elbows are used to change the direction of pipelines, facilitating the layout of pipeline systems in fields. Its high pressure resistance and UV resistance make it perform well in outdoor environments.

Advantages of Plastic UPVC 90-degree Elbows

Strong Corrosion Resistance

UPVC materials have excellent chemical corrosion resistance and can resist the erosion of various corrosive liquids such as acids and alkalis, and are particularly suitable for harsh working environments.

High Strength and Lightness

Plastic UPVC 90-degree elbows have high compressive strength and can withstand high pressure inside the pipeline. At the same time, the density of UPVC materials is low, and the elbows are light in weight, which is easy to install and transport.

Easy to install

Due to the simple design and connection method of the plastic UPVC 90-degree elbow, its installation process is very convenient. Especially when the adhesive connection is adopted, the installation time is short and it has high reliability.

High cost-effectiveness

Compared with metal materials, the production cost of UPVC 90-degree elbow is low and it has a good cost-effectiveness. When used on a large scale, it can greatly reduce the cost of construction and maintenance.

High temperature resistance and weather resistance

Although the high temperature resistance of UPVC material is limited, its weather resistance is very good. Even if it is exposed to the sun for a long time, it is not easily affected by environmental factors and maintains good performance.

Future development trend

With the popularization of green environmental protection and energy-saving concepts, the market demand for plastic UPVC 90-degree elbows will continue to grow. In the future, the design of UPVC elbows will pay more attention to environmental protection, energy saving and intelligence, especially in improving production efficiency and reducing energy consumption. With the continuous advancement of plastic processing technology, UPVC materials will be improved to enhance their performance in extreme environments, provide longer service life and lower maintenance costs.

As an important accessory commonly used in pipeline systems, plastic UPVC 90-degree elbows are widely used in many fields such as building water supply and drainage, chemical transportation, ventilation, electrical pipelines and agricultural irrigation due to their unique performance advantages. With its corrosion resistance, high strength, convenient installation and low cost, plastic UPVC 90-degree elbows have become an indispensable part of modern pipeline engineering. With the continuous development of technology, the future plastic UPVC 90-degree elbows will be more efficient and environmentally friendly, meeting the needs of more industries for pipeline systems.