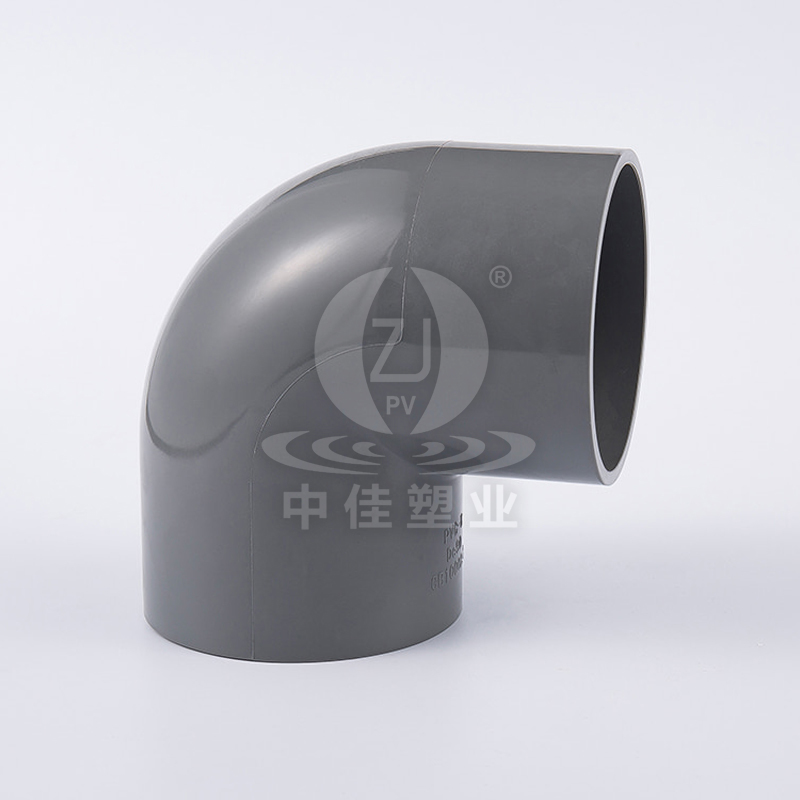

Brand: Zhongjia

Material: PVC-U

Size: DN15 to DN100

Technique: Injection moulded

Color: Dark gray

Standard: DIN standard

Nominal Pressure: PN10

Origin: China

High-quality components are essential for the reliable and efficient operation of piping systems. Whether in the chemical process industry, microelectronics or water treatment: Zhongjia's Plastic valves reliably covers a variety of applications with its broad product range.

The ball valve uses a rotating ball with a hole through it that allows straight-through flow in the open position and shuts off flow when the ball is rotated 90º to block the flow passage.

This valve is primarily used for open/close functions and for throttling services.

Product Features and Advantages:

● Variety. Zhongjia offers a wide range of ball valves, available in different materials and dimensions.

● Durability. State-of-the-art production and testing facilities ensure uncompromising quality, thus guaranteeing high quality and a long service life.

● User-friendly. The ergonomic form of the ball valve lever enables user-friendly operation.

● Simple installation and removal due to compact construction, Simple maintenance and long service life.

● Low torque opening and closing.

Brand:

Zhongjia

Material:

PVC-U

Size:

DN15 to DN100

Technique:

Injection moulded

Color:

Dark gray

Standard:

DIN standard

Nominal Pressure:

PN10

Origin:

China

In modern construction, industry and municipal engineering, the efficient operation of piping systems is essential. As an important part of pipeline connection, PVC-U pipe fittings (PVC-U Coupling) has become one of the ...

In modern pipe systems, UPVC (Unplasticized Polyvinyl Chloride) materials are widely used due to their excellent corrosion resistance, light weight, high strength and easy installation. UPVC Socket Union is an important ...

In modern buildings, water supply and drainage, ventilation and other piping systems, pipe connection and turning are crucial links. Plastic UPVC Elbow 90 Degree is a common pipe fitting widely used in various industrial...

How Low Torque Operation Benefits PVC-U True Union Ball Valves

PVC-U True Union Ball Valves are widely recognized for their reliability, versatility, and efficiency in various applications, ranging from chemical processing to water treatment. Among their many advantages, the low torque operation stands out as a critical feature, offering practical and economic benefits to users. This characteristic makes these valves easy to operate, reducing the physical effort or mechanical assistance needed to open and close the valve, even under high-pressure conditions. For operators and systems requiring frequent adjustments, this feature significantly enhances user experience and operational efficiency.

The benefits of low torque operation extend beyond ease of use. It reduces wear and tear on the valve's internal components, such as seals and the rotating ball, ensuring a longer service life and consistent performance. Additionally, low torque requirements minimize the strain on actuators or automation systems, which is particularly advantageous in industrial settings. By demanding less energy and reducing maintenance needs, these valves contribute to overall system reliability and lower operational costs, making them an ideal choice for professionals seeking cost-effective solutions.

At Zhongjia, we integrate advanced production techniques and rigorous testing to ensure our PVC-U True Union Ball Valves deliver uncompromising quality. The ergonomic design of our valve levers not only enhances ease of operation but also aligns with our commitment to providing user-friendly and durable products. With a compact construction that simplifies installation, removal, and maintenance, our valves are engineered for practicality without sacrificing performance.

Impact of Temperature and Pressure on PVC-U True Union Ball Valves

PVC-U True Union Ball Valves are designed to perform reliably under a range of temperature and pressure conditions, making them ideal for diverse applications such as chemical processing, water treatment, and microelectronics. These valves are inherently resistant to corrosion and chemical reactions, but their performance can still be influenced by environmental factors. High temperatures can soften the material, potentially affecting the seal integrity and structural rigidity, while extremely low temperatures might make the material more brittle. Similarly, excessive pressure beyond the valve's rating could strain its components, leading to wear or failure over time.

To mitigate these challenges, it is crucial to select a valve that is appropriately rated for the specific temperature and pressure conditions of the intended application. At Zhongjia, we manufacture PVC-U True Union Ball Valves with high-quality materials and precise engineering to ensure their durability and reliability. Our valves are rigorously tested to withstand standard industrial pressures and a range of temperatures, offering consistent performance in demanding environments. This commitment to quality ensures that our products maintain their structural integrity and operational efficiency, even when subjected to variable conditions.

One of the key advantages of PVC-U as a material is its excellent chemical resistance, which remains stable within the operational temperature range. However, when operating near the upper or lower temperature limits, users must account for potential changes in pressure tolerance. Zhongjia’s valves are designed with this in mind, offering enhanced resistance to thermal expansion and contraction. Additionally, their compact design and tight sealing mechanisms ensure that fluctuations in pressure do not compromise the valve's functionality or the overall system's efficiency.

PVC-U

PVC-U Pipes PVC-U Fittings for Industry PVC-U Fittings for Water Supply PVC-U Pipes ASTM D1785 PVC-U Fittings ASTM SCH80

Copyright © Changzhou Zhongjia Plastic Industry Co., Ltd. All rights reserved.

Copyright @ Changzhou Zhongjia Plastic Industry Co., Ltd. All Rights Reserved.