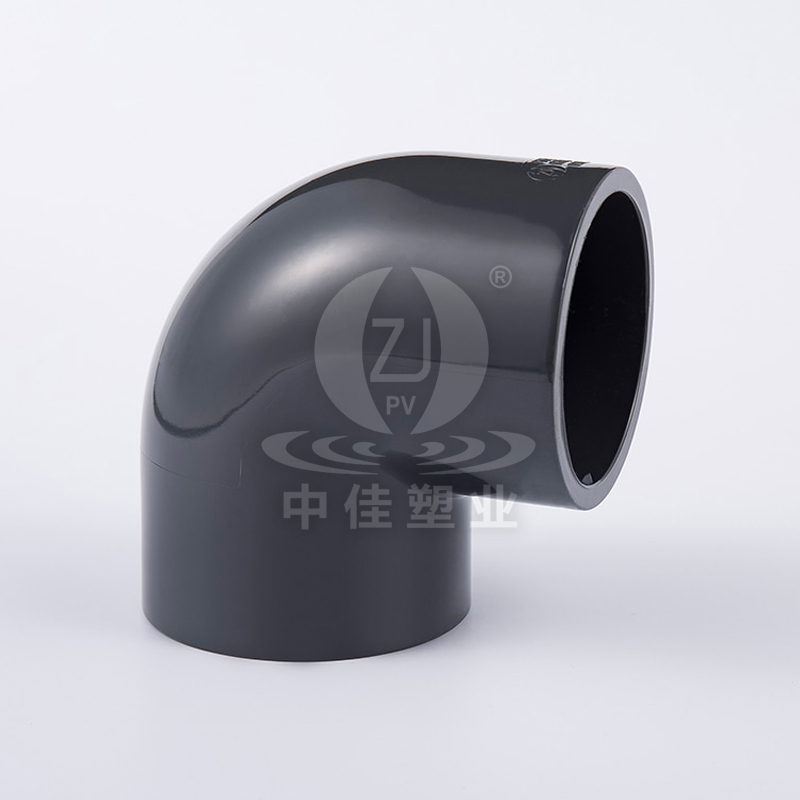

UPVC pipe fittings are an indispensable and important part of modern construction, industry and municipal engineering. As a high-performance plastic pipe fitting, UPVC (unplasticized polyvinyl chloride) is widely used in water supply, drainage, sewage treatment and chemical industry with its excellent corrosion resistance, durability and economy.

UPVC material has extremely high chemical stability and can resist the erosion of various chemical substances such as acid, alkali and salt. This makes UPVC pipe fittings particularly suitable for corrosive environments such as chemical industry, sewage treatment and seawater transportation.

Lightweight and easy to install

UPVC pipe fittings are light in weight and easy to transport and install. At the same time, its connection method is simple (such as adhesive connection or threaded connection), which greatly shortens the construction time and reduces labor costs.

High durability

UPVC pipe fittings have excellent anti-aging performance and mechanical strength, and can be used for a long time in various harsh environments, with a service life of more than 50 years. In addition, they also have good impact resistance and wear resistance.

Environmental protection and hygiene

UPVC materials are non-toxic and harmless and will not pollute water quality, so they are widely used in drinking water delivery systems. At the same time, UPVC pipe fittings can be recycled, which is in line with the development trend of green environmental protection.

Economical

Compared with metal pipe fittings, UPVC pipe fittings have lower production costs and less maintenance costs, making them a very cost-effective pipeline solution.

Production process of UPVC pipe fittings

The production process of UPVC pipe fittings mainly includes the following key steps:

Raw material preparation

The main raw material of UPVC pipe fittings is unplasticized polyvinyl chloride resin, supplemented by additives such as stabilizers, lubricants and pigments. These raw materials are mixed evenly after precise proportioning to ensure the stable performance of the final product.

Extrusion molding

The mixed raw materials are heated to a molten state and injected into the mold through an extruder to form the desired pipe shape. This process requires strict control of temperature and pressure to ensure the dimensional accuracy and surface quality of the product.

Cooling and shaping

The formed pipe fittings enter the cooling water tank for rapid cooling to fix their shape and increase their strength. The cooling speed and uniformity are crucial to product quality.

Finishing and testing

The cooled pipe fittings need to be cut, trimmed, and checked for appearance, size and sealing performance to ensure compliance with industry standards.

Application areas of UPVC pipe fittings

Building water supply and drainage

UPVC pipe fittings are widely used in hot and cold water supply, rainwater drainage and sewage drainage systems in residential, commercial buildings and public facilities. Its corrosion resistance and hygienic properties make it an ideal choice for building pipes.

Municipal engineering

UPVC pipe fittings are favored for their durability and economy in urban water supply networks, drainage systems and sewage treatment plants. They can effectively cope with chemical corrosion and external pressure in complex underground environments.

Industrial pipelines

UPVC pipe fittings are often used in industries such as chemical, pharmaceutical and food processing to transport corrosive liquids or gases. Its excellent chemical stability and sealing performance ensure the safety and reliability of the production process.

Agricultural irrigation

In modern agriculture, UPVC pipe fittings are used in drip irrigation, sprinkler irrigation and water pipeline systems. Its lightness and durability make it an ideal choice for efficient and water-saving irrigation.

Power and Communication

UPVC pipe fittings are also used as cable protection sleeves for laying power and communication lines. Its insulation performance and pressure resistance can effectively protect cables from external damage.

Future Development Trends of UPVC Pipe Fittings

With the advancement of technology and changes in market demand, UPVC pipe fittings are developing in the following directions:

Research and Development of High-Performance Materials

The research and development of new UPVC composite materials will further enhance the high temperature resistance, high pressure resistance and impact resistance of pipe fittings to adapt to more stringent application environments.

Intelligent Production

The application of automated production lines and intelligent testing equipment will significantly improve the production efficiency and quality consistency of UPVC pipe fittings while reducing production costs.

Green Manufacturing

The promotion of environmentally friendly UPVC materials and recyclable processes will reduce the impact on the environment and promote the industry towards sustainable development.

Customized Services

With the diversification of customer needs, UPVC pipe fittings manufacturers will provide more customized products to meet the needs of specific projects, such as special sizes, colors or functional designs.

UPVC pipe fittings have become one of the core components of modern piping systems with their excellent performance and wide range of applications. Whether in construction, municipal or industrial fields, they have demonstrated irreplaceable value. In the future, with the continuous innovation of technology and the growth of market demand, UPVC pipe fittings will surely play a greater role in more fields and contribute to the sustainable development of human society.